Team News Riveting

Kolkata, June 17

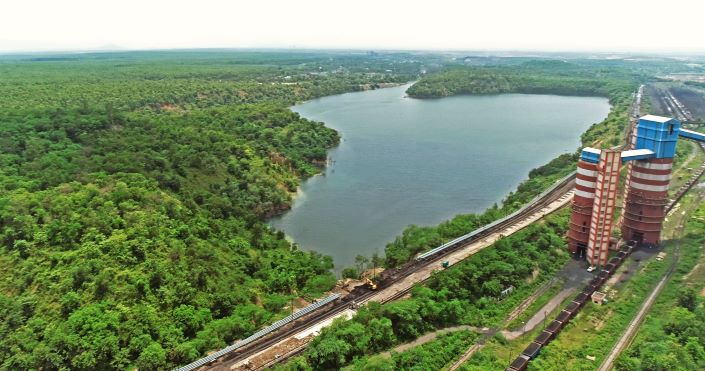

Coal India Limited (CIL) is taking a close look on green mining options in a bid to minimize adverse environmental impact by leveraging a slew of eco-friendly technologies in its UG and OC mines.

With land turning out to be a major pain point for expansion of coal mining operations these technologies bypass land acquisition and avoid its degradation. The locked up coal assets left out earlier due to techno-commercial and safety concerns can now be unearthed through these technologies.

CIL is exploring ramping up its UG production by four-fold to 100 million tonnes (MTs) by FY 2030 from 25.6 MTs in FY’22. UG output is environmentally clean, minimally invasive on land degradation, society friendly. Around 70% of the country’s coal reserves are conducive for UG mining.

The aim is to make UG production sizably supplement the OC output. At current rate, mineable coal reserves at existing OC will slowly start lowering.

Among mass production technologies, CIL will introduce 50 continuous miners by FY’25 with peak production potential of 25 MT/Y. 21 such machines are already deployed in ECL, CCL and SECL producing 9 MTs/Y.

Two powered support long wall (PSLW) machines operating in ECL and BCCL produced 1.58 MTs in FY’22 against 1.13 MTs in FY’21 posting 40% growth. Two more PSLWs with a total capacity of 4.5 MT/Y are soon to be deployed in BCCL.

In a first, CIL is aiming to mine coal through punch entry in those OC mines which have reached their ultimate pit level. This could be done through a mix of technologies. CIL plans to identify and implement 5 such mines through punch entry in phased manner till FY’24. So that mineable coal assets can be extracted with economic viability.

CIL is planning to deploy 10 High Wall machines in its OC mines during the ongoing fiscal with projected production potential of 5 MTs/Year. With one such project already operational in SECL three more will soon be functional in ECL. One Highwall machine entails a capex of Rs.200 Crs.

Since nationalization in 1975, UG output contracted by 57.7% till FY’22 while OC production expanded by 8.5 times.

What tilted the scales against UG mines was loss incurring production, longer gestation period, lack of skilled labour, unavailability of indigenous equipment, and departmental production cost being high. With multiple options available now UG production could become viable. Important among them are, mass production technologies, availability of indigenous manufacturing units and well trained skilled labour. Outsourcing to contractors would scale down the cost of production. Gestation period is also considerably lower now. With these advantages CIL plans to steadily scale up the locked up UG coal assets.

Paste fill technology is yet another environment friendly frontier which involves high speed stowing technology. This will be compatible with mass production technology. In contrast to conventional sand stowing it uses fly ash to fill the void created by extracting coal from UG mines, which is yet another environmental friendly step. Such system is in advanced stage of implementation in ECL.