Team News Riveting

Raipur, April 23

SAIL-Bhilai Steel Plant that produces high strength TMT Bars with earthquake and corrosion resistant properties for use in big projects of national importance including dams, bridges, flyovers, expressway, tunnels etc is supplying TMT Bars for use in Mumbai–Ahmedabad High Speed Rail Corridor project.

Construction activity in Gujarat section of the project has picked up pace in recent months. With three rakes of TMT 32 Bars despatched to Ahmedabad in recent days, more than 65,000 Tonnes of TMT Bars in 500D grade of different dimensions has so far been supplied for India’s first under-construction high-speed rail line project.

The 508 kilometre long network will pass through Mumbai, Thane, and Palghar in Maharashtra; and Valsad, Navsari, Surat, Bharuch, Vadodara, Anand, Kheda, and Ahmedabad in Gujarat. The bullet train will cover a distance of 508 km in 2 hours and 7 minutes with a maximum operational speed of 320 km/hr. The MAHSR project is being executed by the National High Speed Rail Corporation Ltd. Larsen & Toubro – IHI Infrastructure Systems Consortium that will fabricate & transport 28 steel truss bridges.

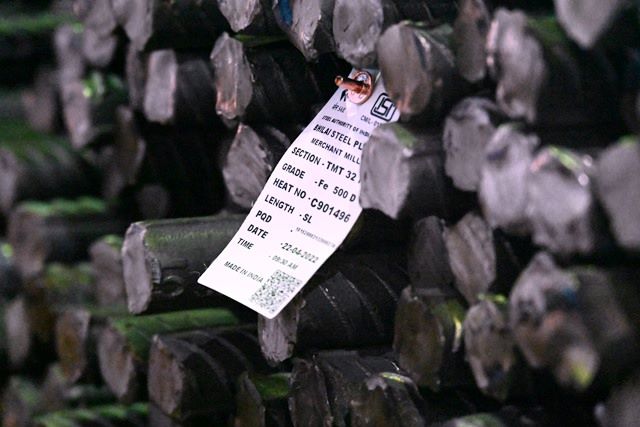

SAIL-Bhilai’s TMT Bars are being used in construction of piers and girders of the High Speed Rail Corridor project that will support the load-bearing capacity of the steel bridges that are being fabricated for laying the bullet train rail corridor. TMT Bars of different dimensions including 8 millimetre, 10mm, 12 mm, 16 mm, 20 mm, 25 mm and 32 mm have been supplied from SAIL-BSP. Of these 25 mm and 32 mm have been rolled out in the Plant’s Merchant Mill and the rest from the Plant’s Modex unit, Bar & Rod Mill.

Products from Bhilai’s Modex unit, Bar & Rod Mill have reached various corners of the country like Nagpur, Vishakhapatnam, Ahmedabad, Hyderabad, Ghaziabad and Jaipur. The superior product quality of products, with negative tolerance and consistent mechanical properties and good weldability produced as per IS-1786 norms, has been widely appreciated by customers of SAIL-Bhilai.

The Plant’s Merchant Mill on the other hand has been rolling out exactly what customers of this highly competitive section of the market are demanding today – steel with the right chemistry for big power and irrigation projects and highrise buildings coming up in seismic and corrosion prone areas. All the TMT bars and rods that the Plant’s Merchant Mill rolls out are in Fe 500 grade with earthquake-resistant properties. Additionally, HCR or high-corrosion resistant properties are also provided to meet customer needs. While Merchant Mill’s entire TMT production is of EQR variety, more sections have been added and corrosion-resistant variety of TMT EQR Rebar is being produced. It is worth mentioning that all TMT products from Bhilai Steel Plant are now being bar-coded before despatch so that upon scanning the bar code, the customer gets to know detail information about the product.

Besides dams, hydro-electric and nuclear power projects, bridges, highways, flyovers, tunnels and highrise buildings all over the country, TMT Bars from SAIL-Bhilai have been used is some landmark projects such as Bandra Worli Sea Link Bridge, Statue of Unity, Agra expressway on which fighter planes have landed and in several bridges & tunnels in North and North-East India.